STEEL PLATFORMS

STEEL PLATFORMS

ANY QUESTIONS?

CONTACT US

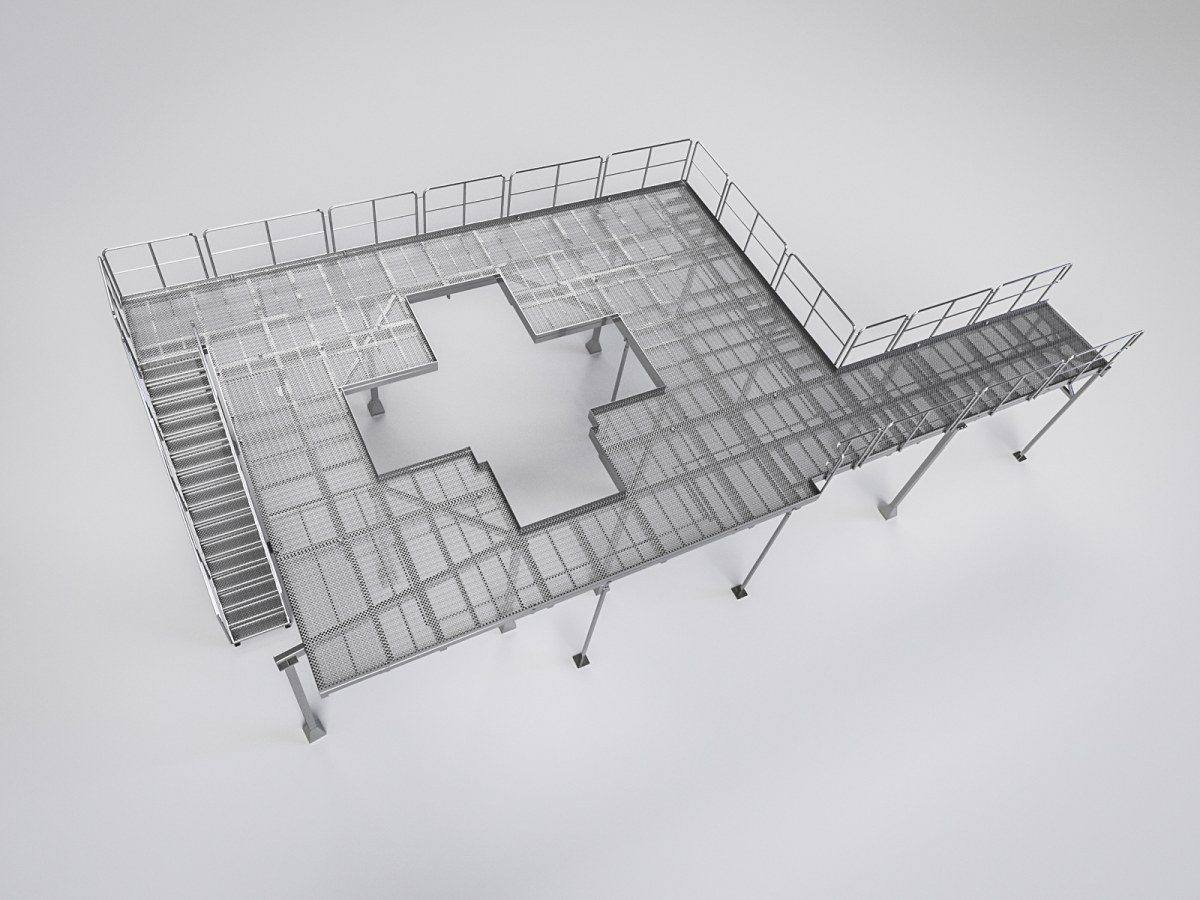

Steel platforms are one of the key elements of every staircase system. They are also known as landings and determine either the beginning of a staircase flight or its end, or are used to connect two points. When it comes to multi-storey buildings, platforms separate metal stair flights between levels.

Steel platforms are generally used to provide free and safe access to rooms or storeys.

ADVANTAGES OF STEEL PLATFORMS

- Traffic possible in several directions

- A place to rest according to imposed standards:

- Technical buildings of 4+ meters height – platform at 3 meters or less

- Public utility buildings – every 17 steps

- Healthcare – every 14 steps

- Exterior – 10 steps

- Give possibility to change stairs direction

- Increase the strength of stairs

- Possibility to install different fillings

our projects

- The steel platform support depends on development’s condition – realization of columns, consoles and mounting are made to fit customer’s structure.

- Investor’s requirements and suggestions are taken into consideration when our design department chooses profiles that will also meet applicable standards.

- Our highly-experienced team of engineers and designers constantly design and verify the structure of steel platforms.

- Every steel platform produced by TLC is made according to Polish, European and global standards depending on their destination. In Poland we follow the Regulation of the Minister of Infrastructure on technical conditions to be met by buildings and their location, for industrial access stairs we follow the PN ISO-14122 – Safety of machinery standards – Permanent means of access to machinery – Part 1-4, Eurocodes and other construction standards.

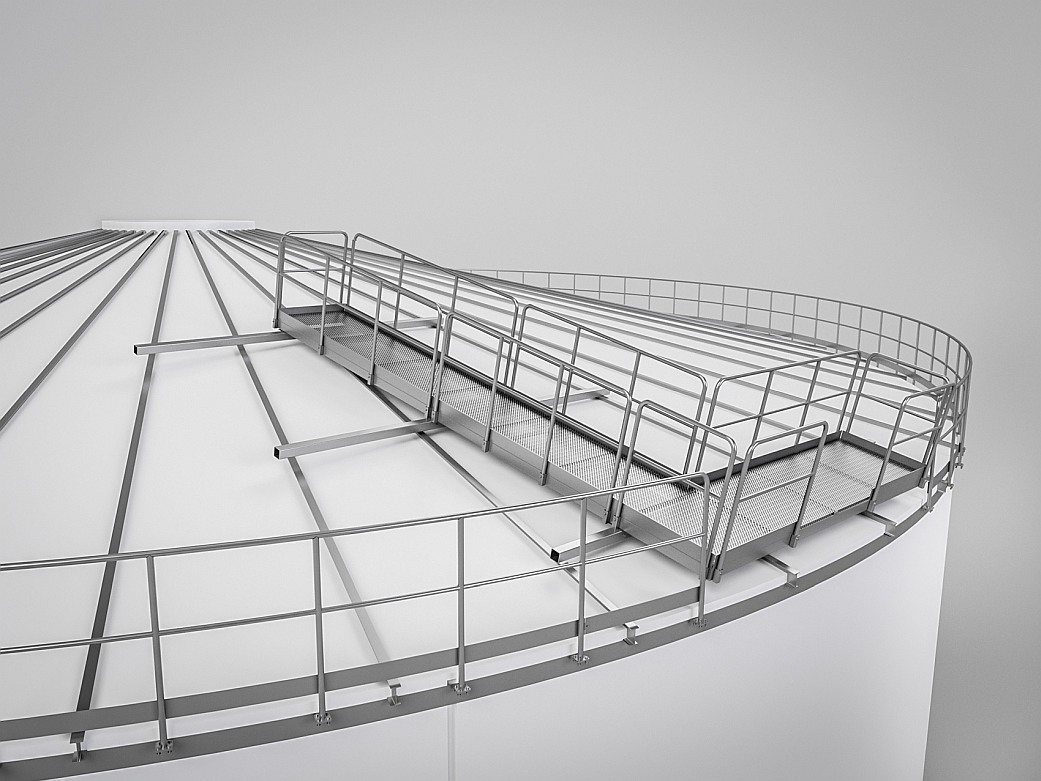

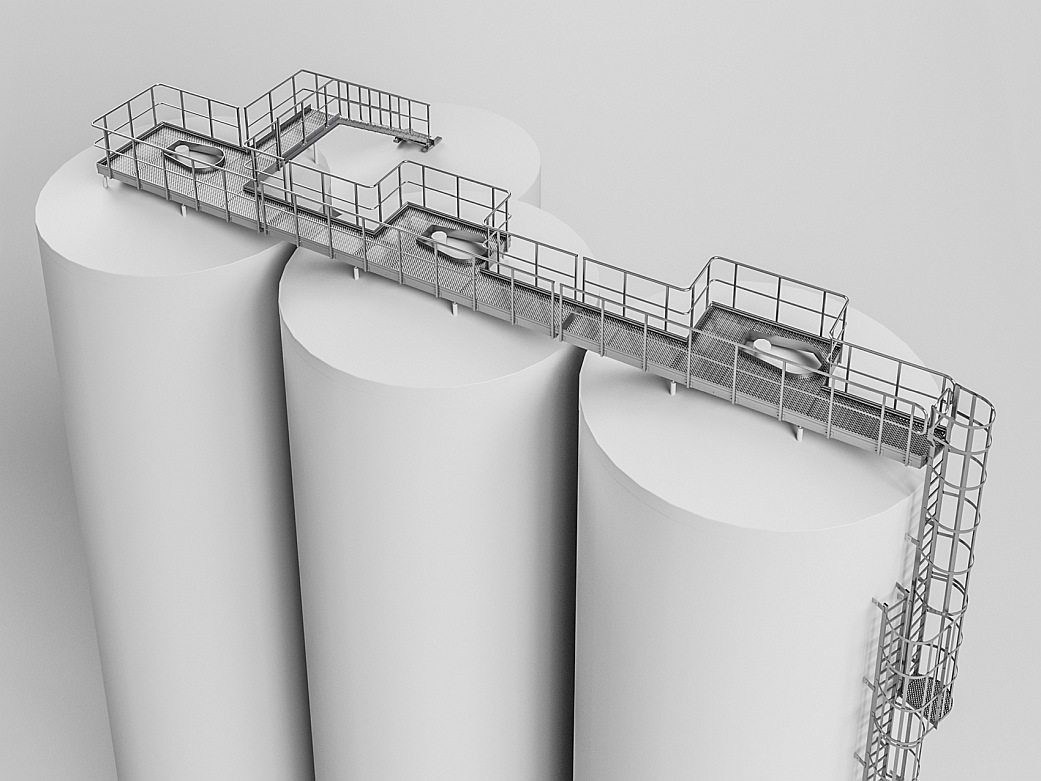

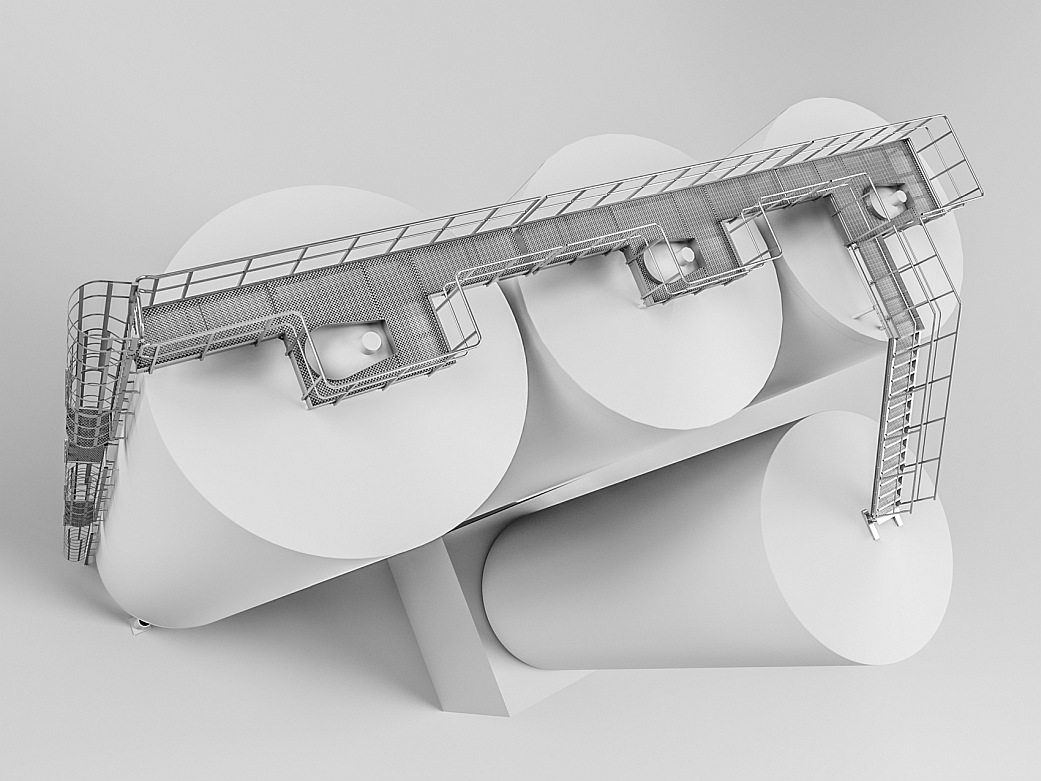

- We are also ready to prepare individual projects – we can make steel traffic platforms, platforms for silos, steel platforms for industrial machinery or access platforms.

- TLC steel staircase platforms are likely to be operating in extreme weather conditions. Therefore, we protect them from corrosion by hot dip galvanization, application of paint coating – a method which proves to be best in particular climate.